The Essential Need for Leak Detection in Liquid-Cooled Data Centers

The Essential Need for Leak Detection in Liquid-Cooled Data Centers

As data centers adopt advanced cooling technologies such as immersion cooling and direct-to-chip cooling, liquid leak detection becomes crucial. Liquid cooling offers significant benefits in terms of efficiency and thermal management, but it also introduces the risk of leaks, which could lead to equipment failure, downtime, or even costly damages. To ensure the reliability and safety of operations, choosing the right leak detection system is key.

Risks and Challenges of Leak Detection in Liquid-Cooled Data Centers

- Proximity of Liquids to Electronics: Unlike air-cooled systems, liquid-cooled infrastructures circulate coolants near sensitive electronic components. This proximity increases the potential for damage in the event of a leak.

- Detection Complexity: Identifying leaks in liquid-cooled systems can be challenging due to the intricate network of pipes and cooling plates, making timely detection crucial.

Consequences of Undetected Leaks

- Hardware Damage: Coolant exposure can cause immediate or gradual deterioration of electronic components, leading to hardware failures.

- Operational Downtime: Addressing leak-induced damages often requires shutting down affected systems, resulting in service interruptions and potential revenue loss.

- Safety Hazards: Leaks can create unsafe conditions, including electrical hazards, posing risks to personnel and infrastructure.

Watch the 3D video showing leak detection for a liquid-cooled data center

Two main techniques for liquid cooling in data centers

- Immersion Cooling

Immersion cooling involves submerging the entire server (or multiple servers) in a dielectric fluid, which doesn’t conduct electricity. The liquid absorbs the heat generated by the hardware components, and the hot fluid is then circulated through a cooling loop where it releases the heat before being reused.

Use case: Used in environments with very high-performance computing needs, such as AI and machine learning data centers, where high-density racks need extreme cooling.

- Direct-to-Chip Cooling

In direct-to-chip liquid cooling, cold liquid is directly circulated through tubes and cold plates attached to the most heat-sensitive components, such as CPUs, GPUs, and memory modules. Heat is transferred from the chips to the cold plates and then to the liquid, which is pumped away to be cooled elsewhere.

Use case: Ideal for high-density servers and racks with powerful processing units that generate a lot of heat.

How to Choose the Right Leak Detection System

When selecting a leak detection system for liquid-cooled data centers, it’s essential to consider the type of cooling method and the liquid used. The system should quickly detect various types of coolants, pinpoint their location, and provide real-time alerts. Additionally, it should be straightforward to install and maintain. By having an efficient leak detection solution in place, data center operators can address issues before they escalate into significant problems.

TTK Leak Detection Solutions for Liquid-cooled Data Centers

To help data centers mitigate the risks of liquid cooling, TTK provides cutting-edge leak detection solutions designed for real-time leak identification and response, specifically tailored for liquid-cooled data centers.

Benefits of TTK Leak Detection Solutions for Immersion Cooling

For data centers using immersion cooling, where entire servers are submerged in dielectric fluids, TTK provides comprehensive protection:

- Full coverage of the entire cooling system, including tanks, CDUs, pumps, cooling towers, and all connected piping.

- Specialized sense cables for conductive and non-conductive liquids.

- Fast and accurate leak detection, preventing potential equipment damage and operational downtime.

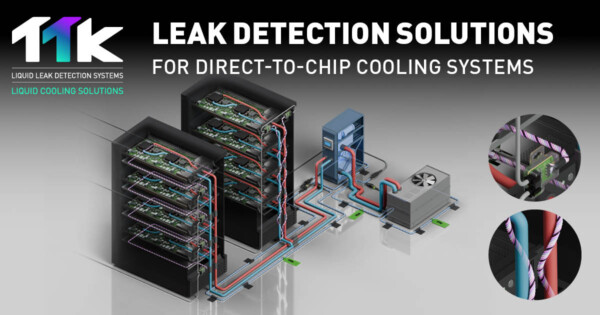

Benefits of TTK Leak Detection Solutions for Direct-to-Chip Cooling

In direct-to-chip cooling, where liquid coolants are circulated through cold plates attached to servers' processors, TTK provides:

- Server-level monitoring to detect leaks around critical components.

- In-rack and above-rack detection, ensuring coverage of all critical areas inside and outside the server rack.

- Pinpoint leak location for quick response and minimal downtime.

Effective detection for various coolant liquids

- Glycol-based coolants (PG25, LC25, etc.)

- Dielectric fluids (Synthetic Hydrocarbons, Biodegradable Dielectric Fluids, etc.)

- Refrigerants

- Conductive & Non conductive liquids

Advantages of TTK Solutions for Liquid-Cooled Data Centers

Liquid leak detection is vital to liquid-cooled data centres' safe and efficient operation. Even a small leak could lead to significant financial and operational losses without a reliable detection system. TTK provides:

- Comprehensive protection for both immersion cooling and direct-to-chip cooling setups.

- Specialized sense cables for all types of liquids.

- Real-time monitoring, with fast and precise leak detection, ensuring minimal disruption.

- Tailored made leak detection systems to meet the specific needs.

- Long Product Life & Low Constraint of Maintenance

As the demand for high-performance computing continues to grow, the adoption of liquid-cooled servers in data centers will only accelerate. While liquid cooling enhances efficiency and performance, it also introduces the critical challenge of leak management. TTK’s advanced leak detection solutions offer smart detection, real-time monitoring, rapid response, reusable sensing cables, and easy installation and maintenance - ensuring comprehensive protection for data center infrastructure.

TTK is ready to safeguard your liquid-cooled data centers with industry-leading leak detection technology. Contact us today to learn more about our solutions.